As one of the initiators of the BeyondBattRec project, Coventry University has taken a bold step toward tackling one of the most pressing sustainability challenges of our time: how to build a truly circular, low-impact battery ecosystem for Europe’s electrified future. At the heart of this effort lies the university’s flagship research facility – the Centre for Advanced Low Carbon Propulsion Systems (C-ALPS) – a hub of next-generation battery and propulsion innovation.

Why BeyondBattRec? The Need for a New Battery Paradigm

BeyondBattRec emerged from this dilemma. and the consortium would not only advance battery recycling but reimagine the entire battery lifecycle – from disassembly and materials recovery to re-manufacturing and second-life applications. The goal: to minimize waste, maximize value retention, and support Europe’s strategic autonomy in battery materials.

Coventry University's Unique Contribution: Powered by C-ALPS

Coventry University’s leadership in BeyondBattRec is rooted in the cutting-edge capabilities of its Centre for Advanced Low Carbon Propulsion Systems (C-ALPS) – the UK’s most advanced facility of its kind. Located in Coventry and spanning 40,000 sq. ft, C-ALPS offers a unique blend of:In terms of recycling efficiency, the regulation establishes a target for lithium recovery from waste batteries, aiming for 80% by 2031. For copper, cobalt, lead, and nickel, recovery targets are at 95% by 2031. These targets may be adjusted based on technological advancements and market developments.

- State-of-the-art battery testing and prototyping labs

- Facilities for cylindrical and pouch cell development, supercapacitor prototyping, and material analysis

- Advanced power semiconductor and hydrogen research laboratories

- EMC chambers, E-machines test benches, and dedicated workshops

- A strong track record in commercialising research, attracting funding from Innovate UK, EPSRC, and APC

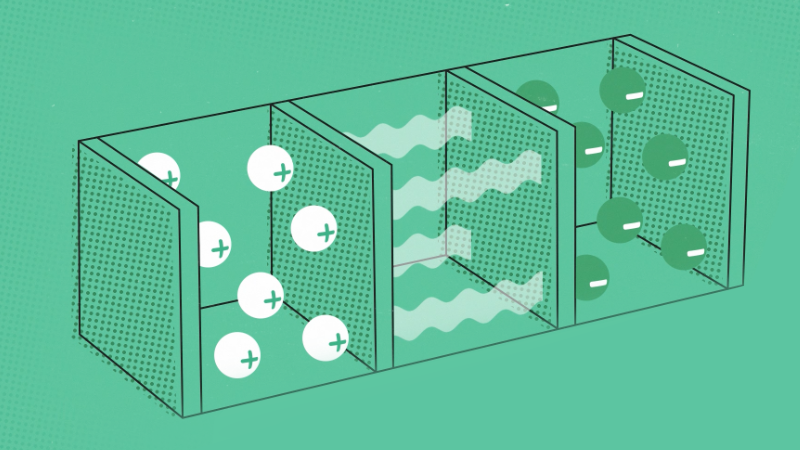

Coventry University plays a central technical and strategic role in BeyondBattRec. Within Work Package 3, the C-ALPS team contributes to the characterisation of black mass and concentrates, developing advanced analysis methods to better understand and sort the valuable components within shredded battery material. This foundational work supports downstream processing and material valuation.

In Work Package 4, Coventry researchers explore direct recovery routes for cathode materials, aiming to preserve functional material structures and improve the efficiency and yield of regeneration processes — a step that could significantly reduce the energy and chemical input typically required in traditional recycling.